SD printed food is here. And it’s going to impact bodybuilding and sports nutrition. Imagine being able to create, in less than a minute, a pre-workout, preservative-free cookie with exactly the nutrient profile your body needs to optimally crank out squats. Or imagine an intra-workout shake mixed, from data transmitted by your body sensors, with the precise ingredients you need to recover from your 60 minutes of back work and recharge for 20 more on the elliptical. It sounds like science fiction, but this nutritional revolution is fast becoming fact. Let’s explore 3D printed food and the future of sports nutrition.

3D PRINTED FOOD

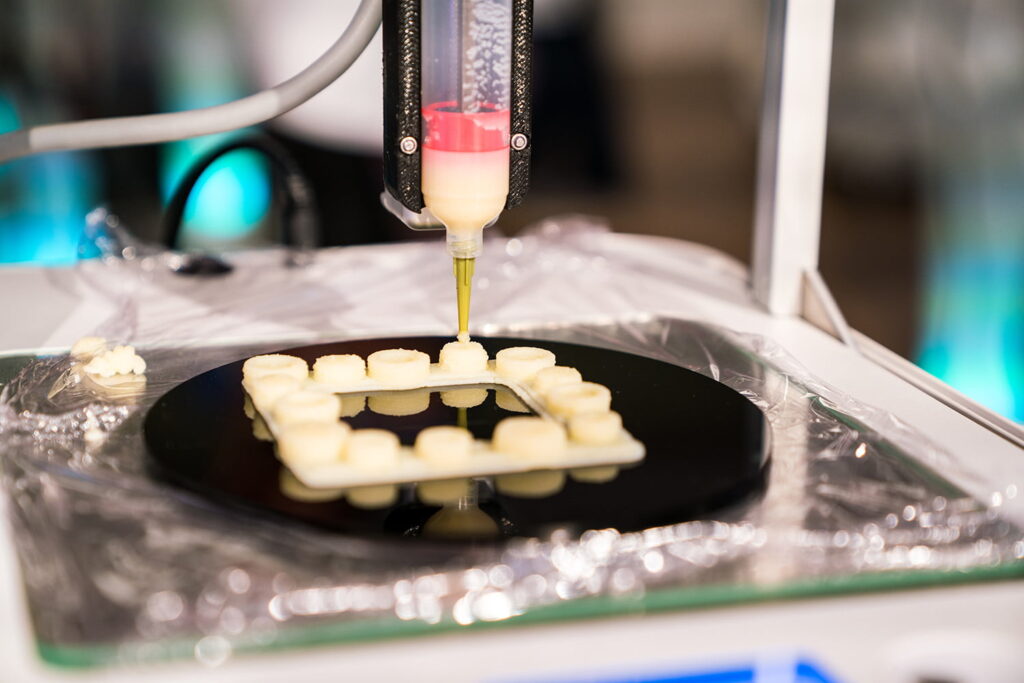

Not only is 3D printed food here, but we’re already in 3D 2.0, having progressed from deposition printing (depositing layers of raw materials) to binding printing (adhering food materials together). The newest food printers use precision nozzles, lasers, and robotic arms to construct in minutes things like pastries so super-finely latticed that no chef could create them in a dozen hours. The pop-up restaurants of Food Ink print almost everything, from tables to silverware to all of their gourmet cuisine.

Beyond the cool factor, printing can create more sustainable fare. Researchers in Germany developed a printing method for microalgae, a plentiful, natural source of protein, carbs, and antioxidants. Though the process seems artificial, meals manufactured to order use only fresh, natural ingredients because there’s no need for preservatives. Natural Machines, maker of Foodini printers, champions its slogan: “Real Food, Freshly Printed.”

A 3D printer can create more-precisely fabricated nutritional supplements and bars. Columbia professor Hod Lipson predicts future machines will deliver foods customized for individuals, providing exact dosages of elements like vitamins, amino acids, and drugs. “Food printing could allow consumers to print food with customized nutritional content, optimized based on biometric and genomic data,” he says. “So instead of eating a slice of yesterday’s bread from the supermarket, you’d eat something baked just for you on demand. This may be the missing link between nutrition and personal medicine.”

Despite the potential benefits, there are still some challenges to overcome for widespread adoption of 3D printed food. Ensuring the safety and quality of printed food products is of utmost importance. This includes maintaining food hygiene, preventing contamination, and ensuring the longevity of printed items. The cost and accessibility of 3D food printers and the necessary ingredients can also be limiting factors for widespread adoption.

NUTRIENT COCKTAILS

This technology’s cutting edge is being explored by the United States Army. Journalist Amanda Little, author of The Fate of Food, explains: “[3D foods] can be printed on demand on the spot and they can be combined with exactly the kind of nutrient cocktail a specific soldier will need. The idea is the soldier will have a sensor sampling sweat or detecting his blood to see if he has a deficit of potassium or needs vitamin C. Then it can transmit that information to the 3D printer, which will then incorporate exactly the nutrients that that soldier needs into a sort of food pellet or food bar and print it out and get it into the field by drone or some other means.”

Little tasted a printed, nutrient-dense peanut butter cup that she called “delicious.” The Army is also experimenting with chickpea flat bread with an avocado paste, all printed on-the-fly.

Less was revealed about the technology behind the monitors, which Little described as a “glorified Fitbit” that deciphered biometric information from sweat chemistry. This is an exciting and rapidly expanding field. Blood samples were also being used, which has both strengths (a more precise reading of nutrient, hormone, and drug needs) and limitations (physically drawing blood, time needed for testing). The Army thinks it’s feasible the monitor-and-printed-food technology will be in the field by 2025.

INDIVIDUALIZED SPORTS NUTRITION

As for fitness, there’s no predicting when we’ll be able to mix up intra-workout foods and drinks because of biometric data gleaned while training. But there is an alternate route, and it might get across the finish line first. If visual workout monitors, like Perch, analyze our every set, and if that information is crowdsourced with millions of examples, an app on our phone may know exactly when our strength, endurance, and energy are peaking and waning, and that same app could tell a 3D printer or robo-blender to make a nutrition bar or mix up a shake with just the right ingredients to better fuel us, not through that workout (too late for that that), but through the next workout. This could be repeated again and again for every workout and recovery period.

We can already get a nutrient and hormonal profile of our blood from a simple test. And the ability to 3D print food like bars, cereals, and breads to fit our needs is here, if not yet widely available. One day, perhaps sooner than expected, you might go to your local GNC to have blood drawn by a nurse (or have it done by a lab and sent to Amazon, Bodybuilding.com, or pick your favorite site). And soon thereafter, you’ll be able to buy foods printed just for you. The old health food store might just become the new print shop.

For more on that high-tech future of fitness, check out: